Fleximate® Integrated Transport Brake Systems

Fleximate® Integrated Transport Brake Systems

Worksmart has three options for stopping or positioning carts to assist assembly techniques or to integrate the cart and WIP with a process.

Friction Brake

Friction Brake Assembly is a simple braking system with easy pressure adjustments. The cart rolls in to the Friction Brake Assembly where the wheels are captured by the Friction Brake. When the assembler has completed their task, a slight pressure releases the cart which rolls to the next position. The Friction Brake does not provide exact position of a cart.

| Standard | ESD | |

| Friction Brake Assembly | 30001 | 35001 (w/aluminum fittings) |

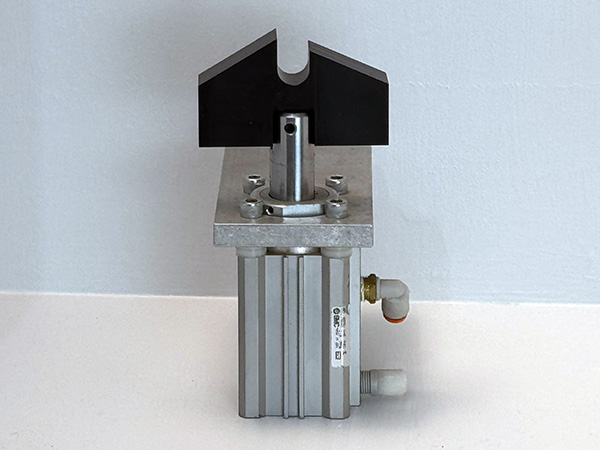

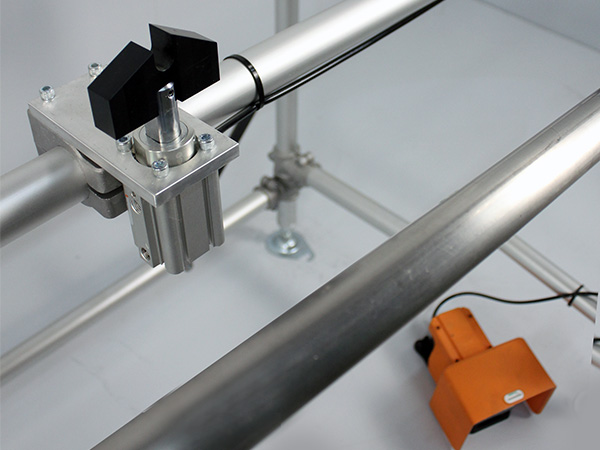

Pneumatic Brake

The spring-loaded, pneumatic cart stop can be used to stop and locate the cart for integrated functions such as pressing, driving and torque applying operations.

In operation,a Fleximate Cart is equipped with the optional Striker Bar assembly (#80083) When the cart arrives at the station. the spring-loaded cart stop will latch onto the striker bar, located on the bottom of the cart. This provides the operator with a stationary work platform. Once the assembler has completed their task, actuation of the pneumatic foot pedal retracts the brake from the striker bar and allows the cart to be flowed to the next assembler or position.

This cart stop also can be interfaced with automation equipment by using reed switches to sense the location of the cylinder motion. This stop also be integrated with sensors for Poka Yoke, error proofing. It is provided with all fittings, air tubing and a foot pedal.

The spring-loaded cart stop will latch onto the striker bar, located on the bottom of the cart, when the cart arrives at the station. This gives the operator the ability to assemble the product on the cart without movement. Once the assembler has completed their task, actuating the foot pedal releases the brake from the striker bar and allows the cart to be moved to the next assembler/position.

The Pneumatic Brake requires 80-90 psi pressure.

| Standard | ESD | |

| Spring Loaded Pneumatic Brake with Foot Pedal | 30010 | 35010 (w/aluminum fittings) |

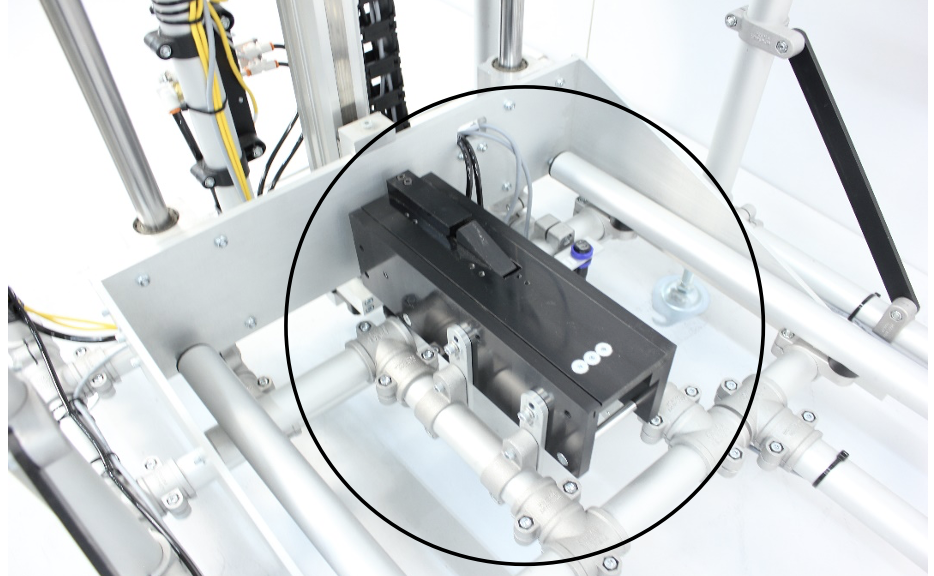

Lock and Go

A striker bar (#80083) on the underside of the cart body is used to interface with the Lock and Go Braking System.

The Lock and Go Braking System performs two functions. If will retain a cart in position within +/- .020. This is achieved by the striker bar on the underside of the cart riding up and over spring loaded jaws. At this point the cart’s striker bar is retained between the jaws by spring pressure on the underside of the jaws.

The second function that Lock and Go performs is that it will propel the cart as it is released from the jaws. It does this with a horizontally mounted air cylinder that simultaneously pulls down the forward jaw and extends forward.

The cart propulsion capability can be used to assist in the flow of carts and WIP between operator positions to minimize worker movement.

The speed which the cart is pushed forward can be adjusted with flow control mounted on the cylinder. The Lock and Go is actuated by a foot switch, but hand controls are available. It will operate between 30 + 120 PSI + CFM and all fittings are included.

The Lock and Go Braking System is constructed from nylon for low friction and long wear. The Lock and Go mounts to the FlexiMate® Integrated Transport workstation with universal fittings that are included.

| Standard | ESD | |

| Lock and Go Braking System | 50020 | 55020 (w/aluminum fittings) |