The simplicity of the Fleximate Transport Line allows your team to add fixtures, tooling, error proofing, and manufacture and test equipment to the line. Our many accessories can be utilized to further your manufacturing program. If you are pressed for time on your rollout, we can integrate components and create tooling to meet deadlines. The following accessories were developed to provide solutions for systems integration. Please visit our Case Study Videos to see some of our novel manufacturing solutions.

Flexi-Flow Drive

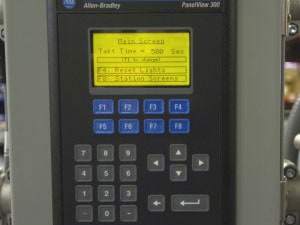

Automation

Worksmart®’s Fleximate® transport line can be provided with a powered means of driving carts between assembly cells. Applications include a paced line, a long return track, or a return track in a “U” shaped cell. To meet these requirements we have developed two modular belt drive systems: The Flexi-Flow and the Friction-Flow, which are mounted between the transport line track sections and workstations. Motive power is supplied by a fractional horsepower 120v AC or 90v DC reduction gear motor with a variable speed drive.

Power from the belt is transferred to the carts via a striker bar assembly fastened to the underside of the cart body. Proximity switches, photo sensors, E-stops, signal lights and other controls can be provided to meet your specifications and codes. Both systems are inherently safe as lifting one end of a cart breaks contact between the striker bar and the belt.

Lock & Go

Worksmart®’s Lock & Go option #50020 performs two functions. It will retain a cart in position within plus or minus .20″. A striker bar on the cart underside is held between the jaws of the Lock & Go by spring pressure. Secondly, a horizontally placed air cylinder will release and propel the cart along the line. The speed can be operator adjusted by using the flow control valve mounted on bottom of the cylinder. It is activated by foot switch or hand controls and operates between 30 + 120 PSI + CFM.

Spring Loaded Stop

The Spring Loaded Stop #30010 features an angled Delrin block on a normally extended spring loaded pneumatic cylinder. The Striker Bar on the underside of the cart travels up the face of the block and lodges in a cut out detent in the block. To release the cart, the pneumatic cylinder is retracted.