This video library provides an overview of both standard and custom cells which Worksmart Systems has designed and constructed with our Fleximate Transport Lines. Our system is a hybrid of an ergonomic workstation and a conveyance. The basic building block is a modular workstation constructed with 1.5” od anodized aluminum tubing and fittings with a pair of horizontal tubes. A Fleximate Transport Cart rolls on the tubes moving the production from position to position. The stations are connected together by the track tubes to create a custom cell. The Fleximate Transport carts are available it two standard sizes 12” deep x 18” long and 18’ deep x 22” long. Carts are customizable for size, top, fixture details, ESD protection and product rotation.

Case Study Video #1

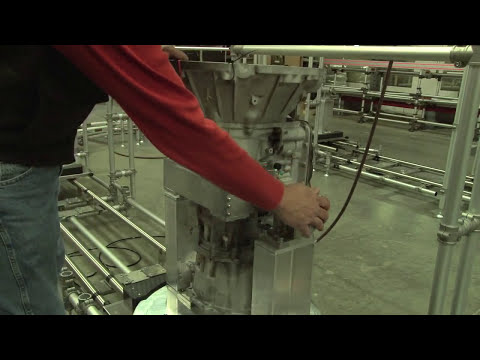

Fleximate Transport Line -Straight ESD Cell with Single Unit Flow, and on Line Test

This 100 foot long cell is an example of a straight ESD cell with a single unit flow on line test for an electro-mechanical high volume product.

Case Study Video #2

Fleximate Transport Line -350# Product 11 Station Cell with Test

This 100 foot long cell is producing a 30” x 39” product and features improved ergonomics, supermarket parts presentation, tool handling, on line test plus many other enhancements.

Case Study Video #3

Fleximate Transport Line- Oval Configuration

Worksmart Fleximate Transport Lean Assembly Cell in an oval configuration performing heavy mechanical assembly with custom rotating trunion fixtures.

Case Study Video #4

Fleximate Transport Lean Assembly Cell- “S” Line

Two long “S” cells in a clean room environment with 250# cart capacity. Also unique cart design for quality control.